Make a Mould and Deckle for Handmade Paper - Cheap, Quick & Dirty

Make handmade paper on the cheap! You may have seen our tutorial on making blender paper from junk mail and scrap papers. Well, here's instructions on how to make a mould and deckle -- it's an essential piece of equipment for the hand papermaking process.

Of course, if you’re allergic to staple guns, you can simply purchase a mould & deckle.

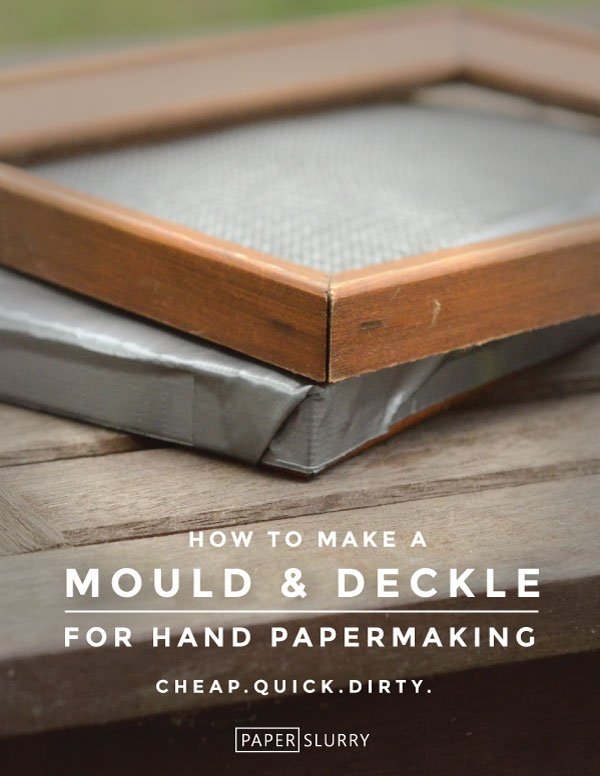

This mould & deckle is not exactly beautiful -- actually, it's ugly and doesn’t last too long -- but it sure does the job when you're on a budget! Or if you just want to try out papermaking for the first time, without having to invest in fancy tools.

At its most reduced form, a hand mould and deckle (in western style papermaking) is simply 2 separate frames of the same size. One happens to have some sort of screening attached (the mould). The other frame stays loose (the deckle). When the deckle is laid on top of the mould, it forms the edge of a piece of paper.

Supplies

2 picture frames - same size, with everything removed - you should be left with just the frames. *If you don’t have old picture frames to repurpose, you can buy 2 canvas stretcher bar frames of the same size—they will last a lot longer than picture frames because the joints are stronger.

Window screening - aluminum or fiberglass

Foam Weatherstrip Tape - it's adhesive on one side, and usually used for doors & windows

Staple gun & staples

Duct Tape

(OPTIONAL) Hardware Cloth- a type of stiff wire mesh used for fencing, screen doors, etc. You’ll need wire cutters, too, if you’re using hardware cloths to make a less-saggy mould screen surface.

(OPTIONAL) polyurethane & paintbrush

STEP 1: CUT THE SCREENING FOR THE ‘MOULD’

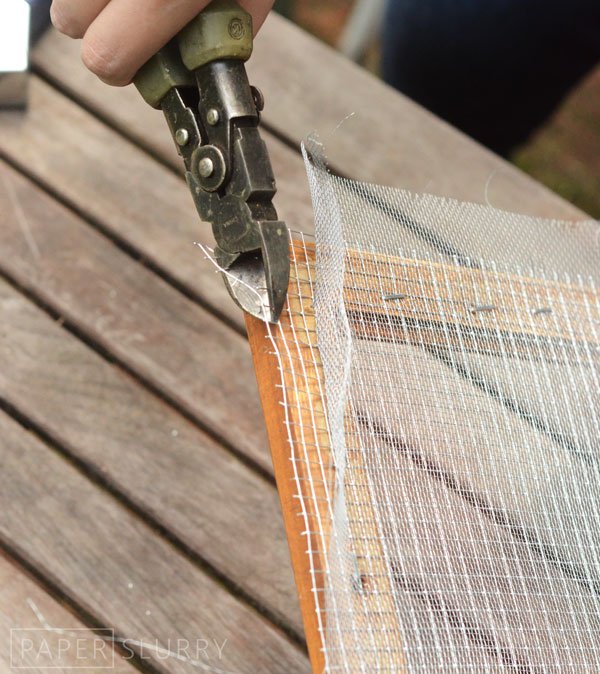

Cut down the window screening using your junky scissors. You’ll want to make it just slightly larger than the picture frame size.

If you want a less saggy mould screen surface (saggy = uneven paper), also cut a piece of hardware cloth (fencing material) using your wire cutters, and to the same size as the window screening. This is what I did with my DIY mould & deckle, shown here.

STEP 2: STAPLE THE SCREENING TO THE FRAME

Find the flattest side of one picture frame. Staple the window screening to the frame. Make sure the screen layer is flat and taut before you start using the staple gun. A good trick is to first place a staple at the center of each edge. From there, keep going around from side to side, working your way outward from each center staple.

Using hardware cloth as a support like I am? Layer the hardware cloth and window screening on the frame together. The window screening should be on top of the hardware cloth. Staple.

STEP 3: TRIM, DUCT TAPE, & WEATHERSTRIP TAPE

Trim off the excess edges, or any violent-looking wires.

Now, time for everyone's favorite fix-it solution -- duct tape! Cover all four edges, making sure not to go past the interior edge of the frame. This helps the pulp not cling to the edges of the screening, making clean-up easier after making paper. It also covers up any pointy edges of the screening, so you don’t poke yourself.

Last but not least - make the deckle! Take the second picture frame (that you haven't touched yet) and apply foam weatherstrip tape. It's adhesive, and you'll want to apply on the flatter backside of the frame, all around the edges. This creates quite a tight seal, and prevents pulp from leaking out between the mould & deckle when you're forming sheets.

If you don’t put weatherstrip tape, your paper edges may be VERY wild and feathery.

FINAL NOTES:

This tutorial is good for smaller, hand-sized moulds. For anything bigger than around 8" x 10", the center of the mould might start to sag, causing issues with sheet formation. You can try cutting and gluing a piece of fluorescent lighting egg crate to fit the backside of the mould, for that extra support.

Also, if your frames need it, you can seal the wood with waterproofing polyurethane. That way, the wood won’t get mouldy from being damp, or as warped over time. Do the polyurethane after the weatherstripping is applied, making sure to let the polyurethane dry completely before making paper.

For some essential mould & deckle nerdery:

An awesome article about the amazing Timothy Moore’s traditional western-style moulds.

A write-up by Michael Durgin on the variation in the world of papermaking moulds.

So, what do you do now?

Want to level up your papermaking game?

Learn how to make a professional mould & deckle that PERFORMS, and doesn’t fall apart or get wonky over time like this one will?

Turn natural pulp into cool papermaking artworks?

Hi, I’m May Babcock, a papermaking artist and founder of Paperslurry.com. I’ve created PAPERSLURRY WEEKLY, an email series that will give you papermaking tips and inspiration every week—it’s 100% free!

Enter your email address at the bottom of this page to become a brilliant papermaking artist: