The Critter Paper Beater is Dandy for Hand Papermaking Studios

Finding a way with limited equipment to beat fiber into paper pulp is one of the biggest obstacles for fledgling attempts at making paper by hand. 'Beating' means processing plant fiber and cloth rags into a pulp with water, that one can then form into paper sheets. Hand beating with mallets works for traditional Japanese fibers and some plant fibers, but can be labor intensive and rough on your biceps. Kitchen blenders only cut fibers, leaving you with a small amount pulp and weaker paper. Hollander Beaters are machines that macerate, cut, and fibrillate fibers into buckets of ready pulp.

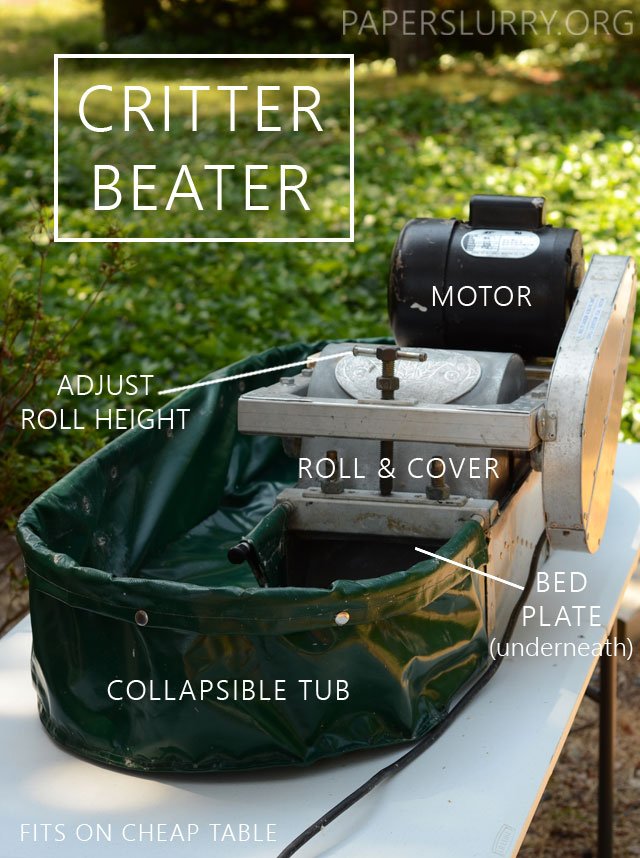

Fortunately, the papermaking community has Mark Lander of New Zealand on their side. Mark builds affordable Hollander beaters, known as Critter beaters. Simple in design, and easy to fix if you're handy, Critters are portable, a little quirky, wonderfully accessible, and available in several sizes. Plant fibers, half-stuff and linters, and even rag can be beaten into pulp with Critter beaters.

History of Little Critters

Mark Lander Critter Papermaking Beater

Fun fact!

Did you know that stacked end to end, Critter beaters stretch taller than the Empire State Building?

The Critter project is not for profit. Mark Lander began hand-making Hollander beaters as a way to provide hand papermakers with a beater at a much lower cost than commercial paper beaters. From the Critter website and Mark himself:

The way it works...I collected enough $ to make machine #1 (with a small wage...it takes about a week to make each machine) and the same parts $ is used again to make machine #2 ...and so on...everything handmade, nothing subcontracted out which would increase prices...the biggest challenge is compensating for exchange rate fluctuations, babies getting born, and communicating the concept of a 'not for profit' to University finance departments. The comforting thing is...there has always been a miraculous component...we have never actually starved, thanks to the goodwill and kindness of our wonderful Papermaking community."

Today, you can find Critter beaters all over the world. The professional practice of hand papermaking has been greatly assisted by Lander's beaters, allowing papermakers on a budget to travel and teach paper workshops, artists to explore the relatively new medium of papermaking, and paper studios to create larger batches of pulp.

Critter Beater Tips & Tricks

Slow but steady wins the race! If you have worked with other Hollander beaters, you might find the Critter to be as slow as molasses. Here are a few things to know:

Beating cloth rag (cotton or linen, cut into 1-inch squares) will take 2.5 to 4 hours. Lower the roll all the way down; you should a low knocking sound, which is a sign that the rag is being processed. Also, only put in enough rag to cover the bottom of the tub.

Water level is crucial for movement around the tub. Make sure the water just covers the highest part of the bed plate. Mark the inside of the tub so that you know how much to fill the tub each time.

Start the machine with the roll up, then immediately lower the roll all the way down. When the pulp is finished, raise the roll for 5 minutes to loose any knots or clumps.

If the fiber is not circulating around the tub, add some already processed pulp, and stir to help it get started. Also, too much fiber or water can sometimes slow movement.

Looking for more information, or have questions about Hollander Beaters or Critter Beaters? Ask away at the Hollander Beaters iO Group a forum on Hollander Beaters: pulp processing, how-to & hints for all makes and models. Or, contact Mark Lander.

Also, here you can read more about Hollander Beaters and where to get one

________________