Here's How to Make Handmade Paper from Recycled Materials

Making paper by hand at home can be a pretty simple process. It's also a fantastic way to use up your old receipts, scrap papers, junk mail, and copy paper that you were about to throw in the recycling bin, and instead create a thing of glorious handmade beauty.

Have those recycled papers hanging around? Some sort of plastic storage tub, and a kitchen blender? With a few supplies and these basic instructions, you're well on your way to making handmade paper and being ridiculously friendly to the environment. Keep reading for the tutorial!

Supplies for Making Paper

Water

Scrap Papers

Plastic storage tub

Kitchen blender, get one from the thrift store

Mould & Deckle, make your own or buy one, it’s the essential tool used to form sheets of paper

2 Wood boards OR sponge & rolling pin

Stiffened felt sheets, towels, wool blankets, cloth, kitchen towels, pellon, Sham-wows, or other flat absorbent material

STEP 1: CUT UP PAPER

Cut or rip up your paper into about 1 inch squares.

Soak your paper for a few hours or overnight.

Drawing, printmaking, and watercolor papers are best because they are generally made from stronger fibers (such as cotton rag, and not chemically treated tree fiber). Your fiber/scrap choice and its characteristics dictate the quality of the final sheet.However, experiment with junk mail, office paper, paper grocery bags, the yellow pages, rejection letters, and more. No plastic, people. Also, experiment with different color combinations.

STEP 2: BLEND IT & MAKE A VAT OF PULP

Fill up a kitchen blender with water. Throw in a good handful or two of the cut up scrap papers (not too much more, or you'll burn the blender motor out). Blend. Keep blending until it's a pulp. Don't make your smoothies with that blender anymore. Have a storage tub hanging around? Those concrete mixing vats from the hardware store also work. Fill up the tub with your blended pulp, about 1/3 to 1/2 way. Add more water to the vat. The more pulp to water, the thicker your paper will be.

STEP 3: PULL SOME SHEETS

For this, you'll need a mould and deckle. It's basically two frames that are the same size, one with screen attached. You can purchase a mould & deckle, or gather supplies to make your own.

Now, for sheet formation:

Stir your vat of pulp.

Hold the mould screen side up, and place the deckle evenly on top.

Holding them together at a 45 degree angle, dip the mould and deckle to the bottom of the vat and scoop up, holding the mould and deckle horizontally.

As you lift it out of the slurry, give it a quick shake back and forth, and left to right to align the fibers and make a more uniform sheet. Stop shaking before the sheet is fully drained.

Let the water drain to a drip.

STEP 4: COUCHING (**Pronounced coo-ching. For real.)

'Couching' means to transfer the wet sheet from the mould to a flat, absorbent surface. Wool felts are ideal, but there are many other options: wool blankets, smoother towels, thick paper towels, non-fusible interfacing or pellon, sham-wows, or bed sheets. Set up your felt with a board underneath and soak your couching materials.

Remove the deckle from the mould.

Place a long edge of the mould on the felt.

In one smooth motion, place the mold face down, press down, and lift from that initial edge. Think of this like a close the door, open the door, motion.

STEP 5: PRESSING

Option 1: Hand Pressing

Place pellon or paper towel on top of your freshly couched sheet. With a sponge, press gently at first, then press firmly with as much pressure as possible. Have a rolling pin or old paint roller? Use that to press your paper even more.

Option 2: Board Pressing

Place another felt on top of your freshly couched sheet. Continue to couch another sheet, layer another felt, and repeat. Layer one final felt and another wood board when you've made a stack. Take the post outside to a concrete or stone surface. Stand on it!

STEP 6: DRYING

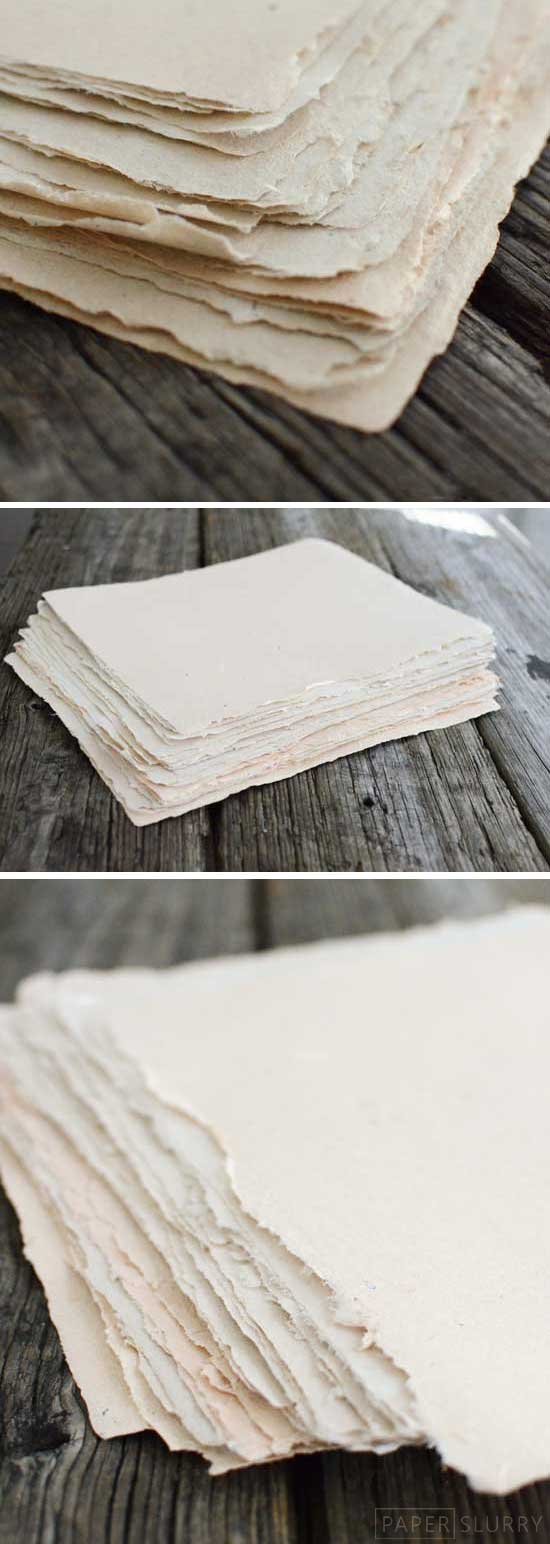

Option 1: Surface Drying (that's this picture here)

Find a flat, non-porous surface. Smooth wood boards, plexiglass, windows, and formica surfaces work well.

Take your wet sheet and gently press onto the flat surface. Make sure the edges are pressed down well.

Let the paper dry (1-3 days depending on humidity levels and thickness of the paper).

Peel it off.

Option 2: Exchange Drying

Get some blotters, towels, or other absorbent, dry, flat material.

Layer the material and then your wet handmade paper on top.

Repeat. Create a stack.

When you're done, place a wood board or a book on top. Weigh it down with more books or something heavy.

Check it once every day and exchange the damp material with dry material until your handmade paper is dry.

Option 3: No Restraint Drying

This one's easy. Take your wet sheet and throw it on a shelf, table, counter...and let it dry. It'll be wild, wrinkly, and textured, but sometimes wild and free is good.

Option 4: Dry on Pellon or Cloth

After pressing, peel and hang up the cloth or pellon (with the wet paper still stuck to it) that you've couched onto, and hang on a clothesline with the top edge of the pellon. Because you've pressed the paper to the pellon, the pellon will restrain the paper as it dries. Once the paper is dry (1-2 days), peel it from the pellon. The paper will be slightly wavy. We dried this paper on smooth plywood.

Also, if you have left over pulp in the tub, you can save it. Take a mesh paint strainer bag, or a fine mesh pasta strainer to drain out all the water. A condensed version of the pulp will be left. Squeeze that into a ball, and let it dry. To reuse down the road, simply soak overnight, rip apart, and blend again.

Thank-you Liz Wikstrom for helping make this tutorial happen, and for making paper!

So, what do you do now?

Want to level up your papermaking game? Make better quality paper that you can actually write on? Turn natural pulp into artistic handmade papers, pulp paintings, sculptures, and more freakin’ cool papermaking artworks?

Hi, I’m May Babcock, a papermaking artist and founder of Paperslurry.com (that’s the website you’re on right now, btw). I’ve created PAPERSLURRY WEEKLY, an email series that will give you papermaking tips and inspiration every week—it’s 100% free!

Enter your email address at the bottom of this page to get started and become a brilliant papermaking artist: